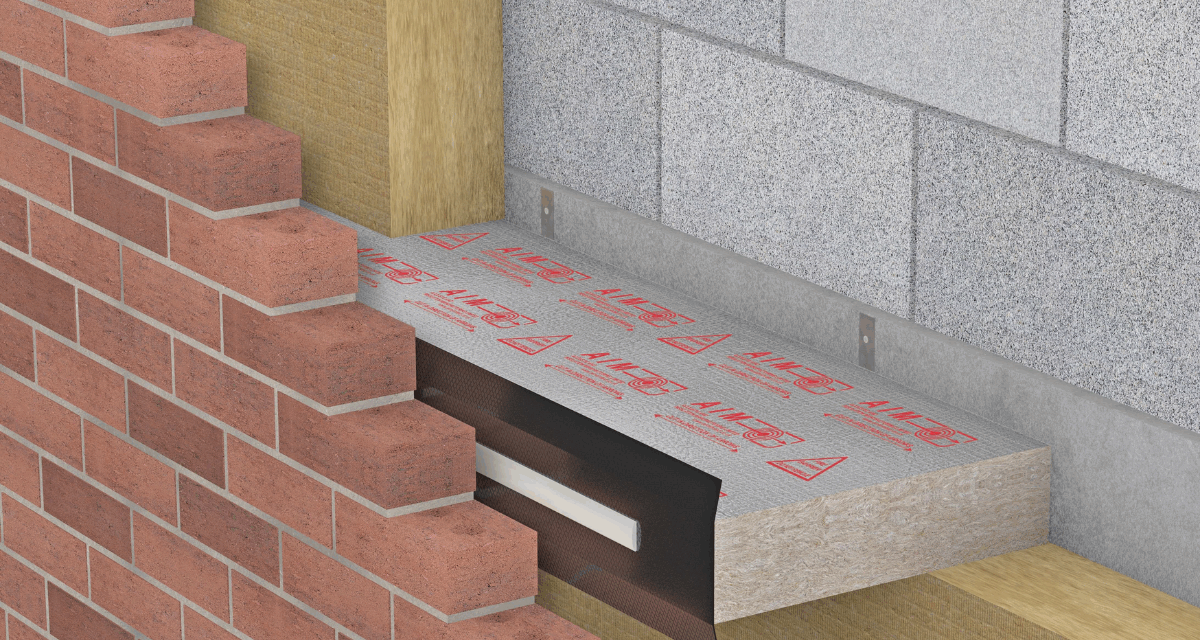

AIM – Acoustic & Insulation Manufacturing has demonstrated that its Wall Cavity Barrier (Red Edition) provides effective fire performance without compression in masonry construction. The new zero compression solution means AIM’s Wall Cavity Barrier (Red Edition) can be installed easily with green brickwork, or other forms of masonry cladding, and avoids the problem of “brick push off” which can be associated with barriers installed under compression.

Acting as a fire and smoke barrier for masonry cavity walls, AIM’s Wall Cavity Barrier (Red Edition) is used to provide a fully closed cavity fire barrier along compartmentation lines in the external cavity wall in a wide variety of construction types, including masonry and SFS. The different barrier thicknesses of 75mm, 100mm and 125mm provide 30, 60 and 120-minute fire ratings to BS EN 1366-4.

Applicable to masonry construction only, zero compression installation has been tested horizontally and vertically for use within voids up to 400mm. The barrier is installed and then the bricks built up against its edge. Once the mortar has set, AIM Acrylic Intumescent Mastic should be applied between the barrier and both substrates. A DPC separating layer can be included if required.

“Tests have demonstrated that the AIM Wall Cavity Barrier is effective without compression in masonry voids, a significant product enhancement that offers far greater flexibility during construction,” explains Ian Exall, AIM’s Commercial Director.

The high-density foil faced stone wool barrier also reduces airborne transmission of sound by a minimum of 21dB RW.

AIM will sell slab versions of the Wall Cavity Barrier (Red Edition) for zero compression applications – not cut barrier. This is so that the installer has total flexibility in sizing of the barrier to exactly suit the cavity void size as required.

Installation details, with a step by step guide, can be found in AIM’s Wall Cavity Barrier (Red edition) Technical Guide, which can be downloaded at: https://www.aimlimited.co.uk/solutions/wall-cavity-barrier/

Part of the Performance Technology Group, UK-based AIM – Acoustic & Insulation Manufacturing has over 30 years of experience in the design, testing and manufacturing of high-quality fire, thermal and acoustic barriers. The company produces a wide variety of bespoke insulation products to customer specification and a range of standard products.