The James Latham Carbon Calculator

Innovation overview and development

An overview of the sustainable innovation

The James Latham Carbon Calculator, is the UK distributor’s latest sustainability-focused innovation, and a worthy contender for the FIS Awards’ Sustainable Innovation category.

Specifically, it’s the first digital tool of its kind to address a long-standing challenge encountered by fit-out professionals when selecting materials in conjunction with a project’s sustainability brief: carbon reporting.

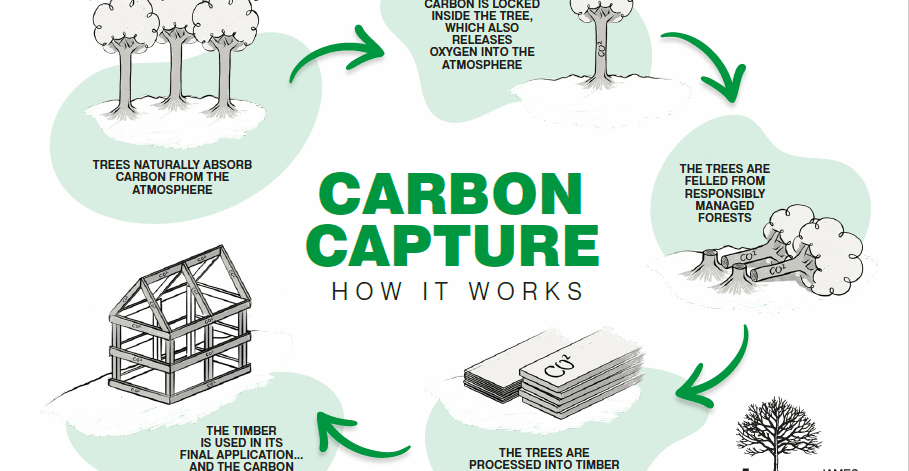

With carbon reporting becoming a compulsory requirement for fit-out professionals, producing accurate and comprehensive reports can be a headache, even for widely accepted green materials, like timber. Although timber is a low carbon option, a lack of consolidated product information can make official confirmation of this claim difficult.

More often than not, fit-out professionals have to take suppliers’ claims at face value, with little or no third-party validation to inspire confidence that the information is complete, or correct.

As a pioneer of sustainable practices in the timber industry, James Latham Ltd (Lathams) decided to tackle the issue head on, making the case for the material category as the lowest carbon construction option.

Launched in November 2021, following two years of R&D, the Carbon Calculator is a sophisticated algorithm-backed digital tool which covers the carbon footprint of all timber products within Lathams’ extensive portfolio. Data is provided on a ‘cradle-to-warehouse’ basis, from growth through to production, then delivery and storage at Lathams Depot.

Essentially, it precisely captures greenhouse gas emissions up to the point the goods leave Lathams’ premises.

12 months on, this service is already helping fit-out professionals, and other customers, make more confident choices, portraying timber in the most positive light and highlighting one of its most compelling and important qualities: its unrivalled ability to capture carbon and reduce CO2.

How the innovation was developed, including effective collaboration, knowledge transfer and partnership along the project team

Serendipitously, two years prior to the Carbon Calculator’s launch, the distributor’s compliance department was undertaking a sustainability-focused quality-assurance exercise. Its overall purpose was to assess the accuracy, quantity and availability of green product information across the distributor’s entire timber portfolio, solely for internal purposes.

When this activity became known to Lathams’ sales and marketing team, they immediately saw the wider potential to help its fit-out professional audience overcome their persistent challenge around correct carbon reporting. After making a compelling case to senior management the project was green lit.

Commencing during the initial stages of the COVID-19 lockdown, when the industry had begun to slow a little, Lathams was able to devote its full attention to developing the Carbon Calculator.

With a commitment to quality at the heart of the business, it was important that Lathams was in a position to devote the significant time and resource required to develop a fit-for-purpose system which delivered ROI for its audience.

With initial research underway, it became clear that an academic partner would be necessary to turn the project from an internal review into a full-blown industry tool.

Following a rigorous selection process, Bangor University was selected as an independent academic institution, to maintain an agnostic approach to the calculator and provide valuable intellectual rigour.

This led to a partnership with the University of Bangor’s renowned BioComposites Centre, with leading researchers Campbell Skinner and George Roberts, working with Lathams to develop the tool.

Two years of R&D ensued in which thousands of documents were collated from a massive pool of suppliers and manufacturers worldwide.

An immediate barrier to overcome was the level of readily available data; some suppliers had far more robust information banks than others. It required a great deal of investigative skill, analysis and patience from the research team to collate such a large amount of data.

From here a robust formula was developed to measure environmental impact, focusing on:

1. Carbon Footprint – The level of carbon emitted during production and delivery

2. Biogenic Carbon – Carbon removed from the atmosphere and stored within the timber’s structure

3. Data Confidence – Lathams’ confidence in the strength of the data used to enable the calculation of the first two criteria (e.g. provenance, integrity of detail)

Each product receives a ‘Confidence’ rating from C1 – C4 (one being the highest), based on the confidence that Lathams has in the data used for the calculations.

The higher the score, the higher the quality of the data points that have been reviewed, for example an audited and published EPD (Environmental Performance Declaration).

The final rating, including carbon data, is then added to quotations, invoices, delivery notes, and other key documentation, delivering a tangible, codified proof point. This ensures a robust audit trail for the product, providing valuable information for future carbon reporting and responding to sustainability briefs.

To trial and further refine the tool, Lathams collaborated with leading carbon-neutral developer Kiss House and ultra-sustainable timber brands Accoya and WISA. This ensured the platform worked effectively end-to-end, and was fit for external release.

Crucially, working with these partners also ensured the Carbon Calculator would deliver on its core objective: providing specifiers and fit-out professionals with codified confidence the timber they select has accurate sustainability information, to improve and facilitate carbon reporting.

The use of new technologies, processes products or techniques or novel uses of existing ones

Evolving the carbon calculator from an internal, compliance-based exercise into an external, commercial-facing system is significant. It proves how Lathams is developing sustainability-led solutions throughout the business in order to support its clients achieve better, higher-value and greener outcomes within their work.

It also highlights the collaborative approach adopted between Lathams’ internal teams, working together to make investments in innovation work as hard as possible, developing solutions which holistically address its audiences’ challenge.

Practically, the Carbon Calculator makes clever use of existing technology and information, bringing previously disparate digital and physical data sets together in one location, aggregating them to inspire greater confidence in selecting from Lathams’ timber portfolio.

Working with the University of Bangor was crucial to achieving this. Their experts were able to help refine and develop a seamless and faultless back-end system, enabling Lathams to collate and evaluate the thousands of documents and certifications which needed to be crunched.

However, the real beauty of the Carbon Calculator can be found in its relative simplicity, user-friendliness and the clear, codified rating for each product which has been evaluated.

Ultimately, it gives fit-out professionals an accurate, topline overview of these products’ green credentials, helping them better make the case for timber solutions within their projects.

Furthermore it’s providing crucial information for reporting which many other competing products lack, ensuring greater compliance.

How does the innovation provide a more environmentally friendly approach for the industry

Encouraging a more environmentally friendly approach for the fit-out industry is at the heart of the innovation’s development.

Fundamentally, the Carbon Calculator was specifically developed to overcome a significant barrier to sustainable specification: accurate, robust and transparent carbon reporting.

Crucially, this tool is providing specifiers with a far stronger reporting framework and metric than has previously existed with the timber category. Not only that, it’s saving considerable amounts of research time trying to source nebulous and not immediately obvious data sets and certifications across multiple supplier portfolios.

Not only is the evaluation produced by the carbon calculator leading to truly lower carbon choices, it’s also saving time, money and energy which would otherwise be spent on information-gathering by the technical team.

From a Lathams perspective, the project has encouraged the distributor to explore new methods and processes which can drive down its own emissions, especially its contribution to it products’ lifetime carbon. The carbon calculator has helped to identify those products where improvements could be made in terms of shipping and logistics, as well as Lathams’ storage facilities and transportation methods.

How does the innovation provide an improvement in social value

The Carbon Calculator is having a positive impact across the timber supply chain.

For example, one of the Calculator’s biggest revelations was that not one product included in the calculator had a larger carbon footprint than the biogenic carbon it contained.

This meant every single product in Lathams’ timber catalogue, whether from Africa, Asia, Europe or the Americas removed more carbon from the atmosphere than it took to harvest, produce, transport and store. Confirming that fact was the biggest win of all.

Increasing use of the Carbon Calculator is also encouraging Lathams’ participating suppliers to reappraise and audit the quality and availability of their carbon credentials.

It’s leading many on a journey of discovery towards greater investment in emissions reduction, ranging from more environmentally-friendly finishing treatments to attaining official certifications such as EPDs, which are becoming a non-negotiable for many specifiers.

This drive towards driving up green standards will, in turn, have a knock-on effect right the way down the supply chain, ensuring more accurate information becomes available for better carbon reporting during the project journey.

For fit-out professionals it means they can select Lathams’ timber with the confidence they are making an informed low carbon option, which will meet the brief, benefit their clients and ultimately preserve the planet.

How does this innovation influence future specifications to improve sustainability

Ultimately, the Carbon Calculator makes a clear-cut case for timber specification within the UK fit-out community, encouraging professionals to move away from higher-carbon alternatives.

As above, it’s also helping to influence carbon reduction activities amongst timber manufacturers and producers which will ultimately result in even lower carbon scores within the category.

On a compliance level it will also improve the accuracy of reporting through more verified data, which will ensure the whole supply chain adheres to increasingly stringent standards and regulations. It will, in turn, give inspectors a far more lucid picture of those businesses which are actually meeting their emissions targets, and those which are not.

By effecting positive, proactive change within the supply chain, Lathams is supporting fit-out professionals, and the wider specification community, in the tough journey to become net zero by 2050. The carbon calculator is one such tool which will support the achievement of this goal.

The feedback received from the industry has been overwhelmingly positive. Customers feel it’s helping them make more confident selections, adding another layer to Latham’s service proposition.

Even competitors have stated what a great innovation it is, and how the UK specification community will massively benefit from such a high degree of materials transparency.